Stirrups are essential in reinforced concrete construction. They help beams, columns, and slabs resist shear forces, prevent buckling, and improve durability. This article explores the meaning, purpose, types, benefits, spacing norms, and their importance in the Indian construction industry.

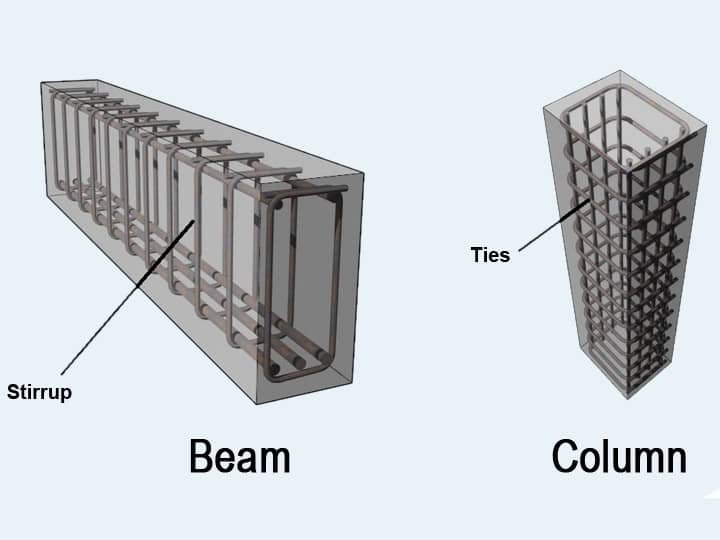

1. What Are Stirrups in Construction?

Stirrups are closed loops or U-shaped steel bars. They wrap around the main reinforcement (longitudinal rebars) in beams and columns. They are also called ties, shear links, or transverse reinforcement.

They form a cage around core bars. This cage holds main bars in position during concrete pouring.

2. Main Purpose of Stirrups

2.1 Shear Reinforcement

Shear forces cause diagonal cracks in beams. Stirrups resist them. They prevent shear failure by transferring forces safely across the section.

2.2 Prevent Buckling of Longitudinal Bars

Under compression or bending, vertical bars (in columns) may buckle. Stirrups hold them in place. They provide lateral support and prevent bending or failure.

2.3 Confine Concrete & Enhance Ductility

In columns, stirrups confine the concrete core. This confinement improves compressive strength and ductility. It helps the column resist seismic forces.

2.4 Hold Main Rebars in Place

During casting, stirrups keep longitudinal bars correctly spaced. This ensures accurate reinforcement geometry. Without stirrups, rebars can shift and cause weak zones.

2.5 Improve Load Distribution and Crack Control

Stirrups help spread load across the section evenly. They reduce stress concentration and crack width. This extends the structure’s life.

2.6 Add Torsional Strength

Beams under twisting or eccentric load benefit from stirrups. They resist torsion and improve stability.

Also Read What is PWD? (Public Works Department) in India: Complete Guide for Engineers, Students & Citizens

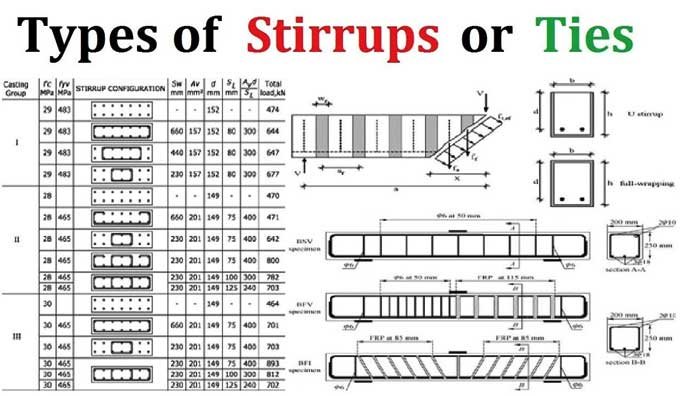

3. Types of Stirrups

| Type | Application | Characteristics |

|---|---|---|

| Closed (Rectangular) | Beams, columns | Full loop; strong confinement |

| Open-Stirrups | Near beam ends, junctions | U or V shape; limited access space |

| Helical (Spiral) | Circular columns, high seismic zones | Continuous coil; uniform confinement |

| Single-leg | Light reinforcement needs | Simple U-shape; rarely used |

| Double-leg | Beams with 4 longitudinal bars | Provides better support |

| Multi-leg (4/6 legs) | Wide or heavily reinforced beams | Encloses more longitudinal bars |

4. Size and Spacing of Stirrups

4.1 Minimum Diameter

As per IS codes and general civil engineering practices, stirrups must not be less than 6 mm in diameter or equal to longitudinal rebars, whichever is greater.

4.2 Spacing According to IS 456:2000

- Maximum spacing: 0.75 × effective depth (d) or max 300 mm for vertical stirrups.

- For inclined stirrups at 45°, maximum spacing ≤ effective depth (d).

4.3 Spacing in Practice (Site Work)

Spacing is closer near supports (high shear regions) and wider near mid-span. In Indian beam design, spacing may range between 100 mm and 300 mm.

Spacing too large reduces shear resistance. Too close may lead to congestion. Design codes guide proper spacing.

5. Advantages of Using Stirrups

- Improved Shear Strength: Prevents sudden shear failure.

- Structural Stability: Holds reinforcement securely in position.

- Better Ductility: Allows structures to deform before failure.

- Durability: Controls cracks and reduces corrosion risk.

- Seismic Resistance: Confined columns resist lateral earthquake forces.

6. Practical Use in Indian Construction

In India, most structures use TMT bars (Fe 415/500) for longitudinal and stirrup reinforcement. Proper detailing ensures safe load transfer and long service life.

Construction crews tie stirrups using binding wire. Welding is avoided due to rust and coating issues. The cage is assembled before concrete pouring.

Engineers follow IS 456:2000 and IS 13920 (seismic design) for spacing, anchorage, and size of stirrups.

7. Summary Table of Functions

| Purpose | Description |

| Shear reinforcement | Prevents diagonal cracks in beams |

| Buckling prevention | Holds vertical bars in place |

| Concrete confinement | Enhances ductility in columns |

| Rebar alignment during pouring | Maintains correct spacing and shape |

| Load distribution and crack control | Limits crack widths and avoids stress points |

| Torsional resistance | Resists twisting forces in beams |

8. Frequently Asked Questions (FAQs)

Q1: Why are stirrups needed when we have main reinforcement?

Main rebars resist tension and bending. Stirrups resist shear forces and lateral movement. Together they make a strong composite.

Q2: What minimum diameter is required for stirrups?

At least 6 mm diameter or equal to the main bars, whichever is larger.

Q3: How does stirrup spacing vary in a beam?

Spacing is closer near supports (where shear is high) and relaxed toward mid-span, as per code.

Q4: Can we omit stirrups in small beams?

No—in smaller beams under shear forces, stirrups are still required by design codes to prevent brittle failure.

Q5: Are stirrups necessary in columns in seismic zones?

Yes, they significantly improve earthquake resistance by confining concrete and preventing bar buckling.

9. Why This Matters in India

Indian buildings often face high shear and seismic loads. Tropical climate causes thermal stresses. Proper use of stirrups is crucial for:

- Safe dwellings and public structures.

- Resistance against earthquakes.

- Durability in harsh weather.

Engineers must follow IS codes, inspect reinforcement cages, and verify tying during site visits.

10. Conclusion

The main purpose of using stirrups in construction is to strengthen beams and columns against shear, prevent buckling, and improve structural integrity and durability. They add vertical and torsional stability, distribute load evenly, and control cracking. Proper sizing and spacing (per Indian Standard codes) ensure structures last long and remain safe.

Stirrups may seem small, but their role is vital. For every civil engineering student, site engineer, or contractor in India, understanding and applying stirrups correctly is essential to good construction practice.