Roads are one of the most important infrastructures in any country. They connect cities, towns, and villages. In India, highways and local roads play a major role in transport and trade. The structure on which vehicles move is called a pavement.

In simple words, pavement is the hard surface layer constructed on the natural ground to provide a smooth and durable platform for vehicles and pedestrians. It distributes the traffic load to the soil below and provides comfort and safety to road users.

This article explains what is pavement in civil engineering, its functions, different types of pavements, and their applications in Indian road construction. The language is kept simple for easy understanding by students, site engineers, and professionals.

What is Pavement in Civil Engineering?

In civil engineering, pavement refers to the layered structure constructed over the soil subgrade. It is designed to carry traffic loads safely and transfer them to the ground.

A good pavement must:

- Be durable and strong.

- Provide a smooth surface for driving.

- Resist wear and tear due to traffic.

- Withstand climate effects like heat, rain, and frost.

- Require minimum maintenance.

Pavements in India are usually constructed using bitumen, cement concrete, gravel, or other highway materials depending on the project and budget.

Functions of Pavement

The main functions of a pavement are:

- Load Distribution – To spread the wheel load from vehicles to the soil below without failure.

- Smooth Riding Surface – To provide comfort and safety to drivers.

- Protection of Subgrade – To protect the natural soil from rain, moisture, and erosion.

- Durability – To resist traffic stresses, weathering, and deformation.

- Economy – To minimize maintenance and repair costs.

Classification of Pavements

Pavements are broadly classified into two main categories:

In addition, there are composite pavements and other special types used in highway construction.

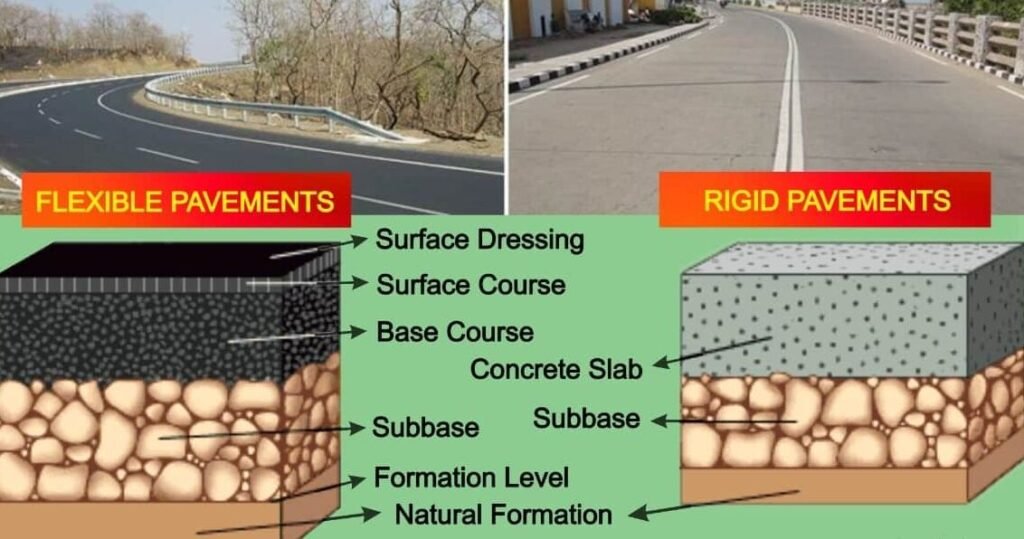

1. Flexible Pavement

Flexible pavement is the most common type in India. These pavements are made of layers of bituminous materials (asphalt), aggregates, and base courses.

The load from vehicles is transferred gradually from the top layer to the bottom layers. Since the layers are flexible, they can withstand slight settlements.

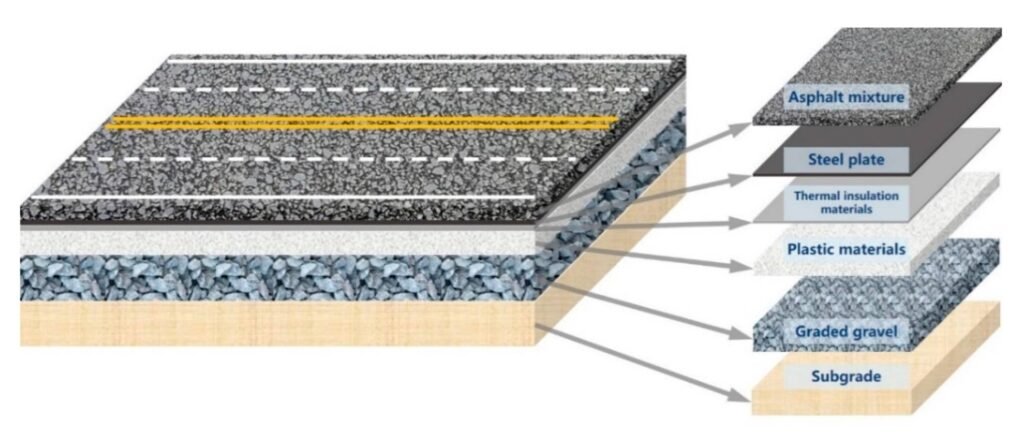

Structure of Flexible Pavement

A typical flexible pavement has the following layers:

- Surface course (bituminous layer) – Provides smooth riding surface.

- Base course – Distributes loads.

- Sub-base course – Provides additional support.

- Subgrade – The natural soil foundation.

Advantages of Flexible Pavement

- Low initial cost.

- Easy to construct and repair.

- Provides comfortable ride quality.

- Suitable for all traffic conditions.

Disadvantages of Flexible Pavement

- Requires frequent maintenance.

- Damaged by water and extreme heat.

- Life is shorter compared to rigid pavement.

Common Uses in India

- National highways and state highways

- City roads and rural roads

- Airfield runways and parking lots

2. Rigid Pavement

Rigid pavements are constructed with cement concrete slabs. Unlike flexible pavements, they distribute the load over a wider area because of their high flexural strength.

Structure of Rigid Pavement

- Concrete slab – Main load-carrying layer.

- Base or sub-base course – Sometimes provided.

- Subgrade – Natural soil.

Advantages of Rigid Pavement

- Longer life (20–30 years or more).

- Requires less maintenance.

- Strong and durable under heavy traffic.

- Resistant to water damage.

Disadvantages of Rigid Pavement

- High initial cost.

- Construction requires skilled labor and proper curing.

- Repairs are difficult once cracks appear.

Common Uses in India

- Expressways and high-speed corridors.

- Urban roads with heavy traffic.

- Industrial and port areas.

- Toll highways.

3. Composite Pavement

Composite pavements are a combination of flexible and rigid pavements. For example, a concrete slab with a bituminous overlay.

These pavements combine the strength of concrete with the smoothness of bitumen. However, they are costlier and used only in selected projects.

Difference Between Flexible Pavement and Rigid Pavement

| Feature | Flexible Pavement | Rigid Pavement |

|---|---|---|

| Material | Bitumen, aggregates | Cement concrete |

| Load transfer | Layer by layer | Entire slab distributes load |

| Initial cost | Low | High |

| Maintenance | Frequent | Low |

| Life span | 10–15 years | 20–30 years |

| Ride quality | Smooth | Less smooth compared to bitumen |

| Suitability | Low to medium traffic | Heavy traffic and expressways |

Pavement Design in India

In India, pavement design is guided by IRC (Indian Roads Congress) codes and guidelines. The design depends on:

- Traffic load (number of vehicles and axle loads).

- Soil subgrade strength (measured by CBR value).

- Climate and rainfall conditions.

- Material availability and cost.

For highways, flexible pavement is more common due to lower cost and easy maintenance, while rigid pavement is preferred in urban and industrial roads with heavy traffic.

Maintenance of Pavements

Pavements need proper maintenance to ensure durability.

For Flexible Pavements:

- Filling potholes with bituminous mix.

- Overlaying with new bitumen layers.

- Drainage improvement to prevent water damage.

For Rigid Pavements:

- Sealing cracks with joint fillers.

- Concrete slab replacement in severe cases.

- Regular cleaning and proper drainage.

Applications of Pavements in India

- Highways and Expressways – National highways, state highways, and industrial corridors.

- Urban Roads – City streets, ring roads, and flyovers.

- Rural Roads – Connecting villages and small towns under schemes like PMGSY.

- Airports and Seaports – Runways, taxiways, container yards.

- Industrial Areas – Roads for heavy truck movement.

Modern Trends in Pavement Construction

In recent years, India has adopted modern technologies for pavement construction:

- Warm mix asphalt for eco-friendly roads.

- Roller compacted concrete pavement (RCC) for heavy-duty applications.

- Permeable pavements for urban stormwater management.

- Use of recycled materials like fly ash, plastic waste, and reclaimed asphalt for sustainable construction.

FAQs on Pavements

Q1. What is pavement in civil engineering?

It is the hard surface constructed over the ground for movement of vehicles and pedestrians.

Q2. What are the main types of pavements?

Flexible pavement, rigid pavement, and composite pavement.

Q3. Which pavement is better in India – flexible or rigid?

Flexible pavements are cheaper and common, while rigid pavements last longer and are used for heavy traffic roads.

Q4. What materials are used in pavements?

Bitumen, aggregates, cement, and concrete.

Q5. What is the life of flexible and rigid pavement?

Flexible pavements last around 10–15 years, while rigid pavements can last 20–30 years with less maintenance.

Q6. What are the latest trends in pavement construction?

Use of recycled plastic, warm mix asphalt, roller compacted concrete, and permeable pavements.

Conclusion – Pavement Types and Their Importance in India

Pavements form the backbone of transportation infrastructure in India. They provide strength, durability, and smoothness to roads.

Flexible pavements are the most widely used in India due to their lower cost and easy repair. Rigid pavements, though costly, are preferred for heavy-duty roads like expressways, toll highways, and industrial areas. Composite pavements are less common but combine the benefits of both.

With growing traffic and rapid development, India needs durable and sustainable pavements. The use of modern construction materials, recycling techniques, and proper maintenance will ensure longer life and better performance of pavements in the future.