In civil engineering, three key concrete types are commonly used:

- PCC – Plain Cement Concrete

- DPC – Damp Proof Course

- RCC – Reinforced Cement Concrete

Each serves a unique purpose. This article explains what they are, why they’re used, key differences, Indian standards, and their roles in modern construction.

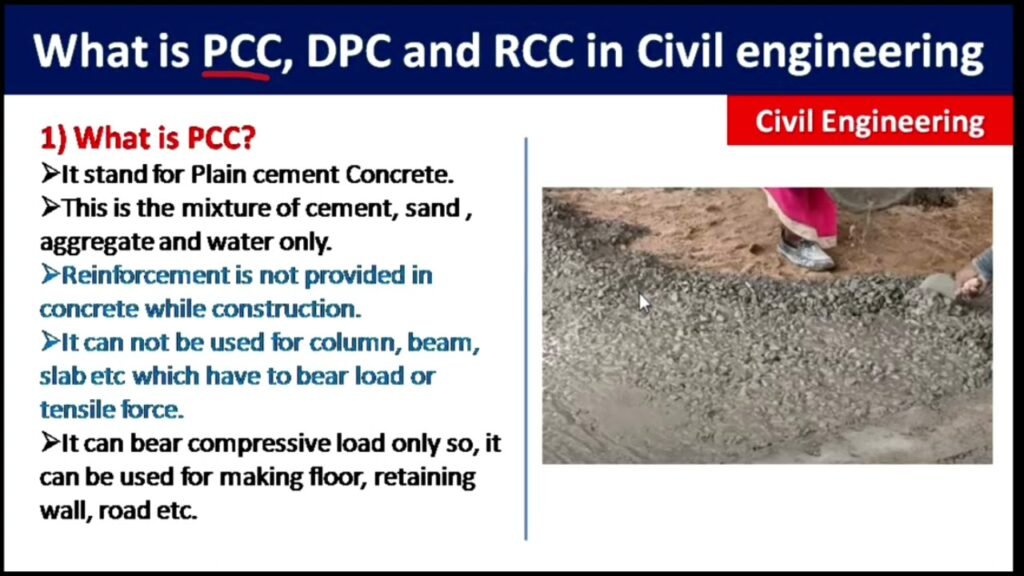

1. What Is PCC (Plain Cement Concrete)?

PCC stands for Plain Cement Concrete, also called binding concrete or mud-mat. It’s a mix of cement, sand, coarse aggregate, and water. It contains no steel reinforcement.

Properties of PCC:

- Good in compression, weak in tension

- Resistance to ground moisture

- Economical and easy to mix onsite.

Common Applications of PCC:

- As a level base for foundations and footings

- Under floor finishes like tiles and marble

- As a sub-base before RCC or block masonry

- As Damp Proof Course (DPC) in low-cost or basic applications.

Typical PCC thickness ranges between 50–75 mm, mixed in ratios like 1:2:4, 1:3:6, or 1:4:8 depending on design requirements.

2. What Is DPC (Damp Proof Course)?

DPC stands for Damp Proof Course—a material layer placed horizontally or vertically in masonry to block the upward movement of moisture.

Key Functions of DPC:

- Prevents rising damp from ground into masonry

- Protects plaster and finishes from moisture damage

- Helps avoid structural decay and health issues in buildings

- Can be made from PCC, bitumen sheet, plastic membrane, mastic asphalt, metal strip, or mortar layers

DPC may be simply part of PCC or a separate damp-proof membrane like plastic sheeting or membrane. It is usually installed at 150 mm above ground level as per Indian building practice.

3. What Is RCC (Reinforced Cement Concrete)?

RCC stands for Reinforced Cement Concrete. It combines concrete with steel reinforcement bars (rebars). This composite material handles both compressive and tensile stresses.

Why RCC Is Used:

- Concrete has high compressive strength but poor tensile strength

- Steel bars provide tensile capacity, making RCC strong in all directions

- Works well under bending, shear, and axial loads

- Includes beams, columns, slabs, footings, and retaining structures

- Critical for earthquake-resistant designs, high-rise buildings, bridges.

Mix design may be nominal (fixed ratio like 1:1.5:3) or design mix based on load requirements.

Also Read Budget Breakdown: 1000 Sq. Ft House Construction Cost in India [2025 Guide]

4. Comparison: PCC vs RCC vs DPC

| Property | PCC | DPC (Layer or Course) | RCC |

|---|---|---|---|

| Full form | Plain Cement Concrete | Damp Proof Course | Reinforced Cement Concrete |

| Reinforcement | No | None (layer only) | Steel bars embedded |

| Compressive strength | Good | Not structural | High |

| Tensile strength | Very low | None | Excellent |

| Common use | Base leveling, flooring etc. | Moisture barrier | Structural framework (beams, slabs) |

| Cost | Low | Moderate depending on type | Higher due to steel and formwork |

| Crack resistance | Prone to shrinkage cracks | Prevents damp cracking | Very good when designed properly |

5. Indian Standard Codes & Mix Guidelines

- IS 456:2000 – Code of practice for plain and reinforced concrete; guidelines for RCC design and mix.

- IS 2660, IS 2572, SP 62 – Guidance for proper execution of PCC and DPC in foundations and masonry.

- IS 383, IS 2386 – Quality standards for aggregates used in all concrete types.

- IS 2064 – Guides DPC installation for moisture protection.

6. Step-by-Step Applications

A. Using PCC:

- Clean and prepare subgrade.

- Mix PCC in correct ratio (commonly 1:2:4).

- Lay in layers <150 mm thick.

- Compact using vibrator or manually.

- Cure for 7–14 days to gain strength.

B. Installing DPC:

- Choose material—PCC, plastic sheet, metal strip, etc.

- Install at least 150 mm above external ground.

- For PCC DPC, provide approx. 50 mm thickness.

- For membrane DPC, ensure proper lap (≥100 mm) and seal joints.

- Ensure DPC spans full thickness of the masonry wall.

C. Casting RCC:

- Formwork must be sturdy and clean.

- Place rebars as per structural drawings (with cover).

- Mix concrete to correct specification (M20, M25, etc.).

- Pour and compact concrete.

- Cure for at least 7 days (preferably 14).

- Core structural elements: beams, columns, slabs, footings.

7. Why These Components Matter in Indian Construction

- PCC provides base and prevents contamination of structural concrete

- DPC stops damp from reaching plaster and walls especially in humid or coastal regions

- RCC forms the strength backbone of modern structures like multi-storey buildings, bridges and public infrastructure

Correctly using PCC, DPC, and RCC ensures durability, avoids cracks, and boosts the life span of buildings.

8. Advantages and Limitations

Advantages:

- PCC: Affordable, simple to lay, prevents soil contact with foundation

- DPC: Effective barrier against moisture, extends plaster life

- RCC: Resists bending, shear, compression, tension; durable and versatile

Limitations:

- PCC: Cannot bear stress other than compression; prone to cracking

- DPC: If installed poorly, may fail to stop moisture—especially with poor lap or punctures

- RCC: Requires skilled labour, proper mix design, formwork and curing; higher cost due to steel

9. Frequently Asked Questions (FAQs)

Q1. Why is PCC used before RCC?

PCC offers a firm, level base and acts as a buffer between soil and RCC. It also prevents water drawn up by soil from entering the main structure.

Q2. Can DPC be made of PCC?

Yes. A 50 mm layer of PCC can serve as DPC if no dedicated damp-proof membrane is used.

Q3. Which parts of a building use RCC?

RCC is used for load-bearing members such as beams, columns, slabs, staircases, and foundations in multi-storey structures.

Q4. What mix ratios are used?

PCC often uses 1:2:4 or 1:3:6 mix. RCC may use nominal mixes (1:1.5:3) or design mixes like M20, M25, depending on load.

Q5. How long should curing continue?

PCC should be cured for at least 7 days; RCC typically requires 7–14 days for optimal strength.

Q6. Can plain concrete bear lateral loads?

No. PCC cannot bear lateral or tensile forces. Only RCC can resist such stresses.

10. Conclusion

Understanding the roles of PCC, DPC, and RCC is essential for designing and executing high-quality construction in India.

- PCC provides the base foundation and sub-level layering.

- DPC protects from moisture rising through surfaces and walls.

- RCC forms the major load-bearing framework of modern construction.

Each has its own material mix, performance characteristics, and application zones. Use Indian standards like IS 456, IS 2064, and SP 62 to guide design and execution.

Choosing the right concrete type at the right place ensures structural integrity, durability, and aesthetics in Indian homes, commercial buildings, and infrastructure projects.