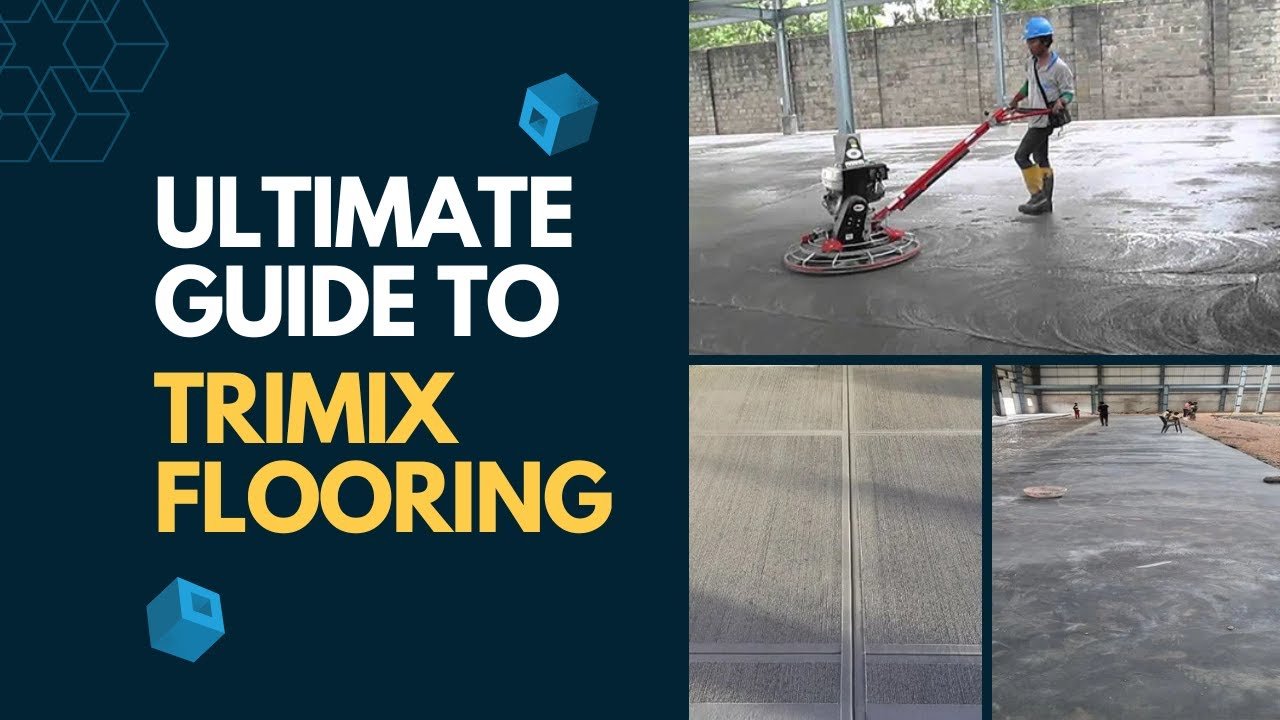

Trimix Flooring, also known as Vacuum Dewatered Flooring (VDF), is a high-performance concrete floor system widely used in industrial construction in India. This flooring technique ensures a hard, smooth, and wear-resistant surface that can withstand heavy loads and traffic.

Whether you’re building a warehouse, factory, or parking lot, Trimix Flooring offers long-term benefits with minimal maintenance. In this article, we explain the entire process, materials, equipment, advantages, cost, and more, using simple vocabulary and short, clear sentences for maximum readability.

What Is Trimix Flooring?

Trimix Flooring is a special type of industrial concrete flooring that uses vacuum dewatering to remove excess water. The result is a dense, strong surface that does not crack easily. The process includes concrete mixing, placing, vacuuming, and surface finishing.

This flooring is ideal for heavy-duty applications such as:

- Industrial sheds

- Warehouses

- Car parking areas

- Commercial spaces

- Airport and railway platforms

🔹 Benefits of Trimix Flooring

| Benefit | Description |

|---|---|

| High strength | Improves compressive and tensile strength |

| Abrasion resistance | Reduces surface wear even under heavy traffic |

| Less water content | Vacuum dewatering leads to denser concrete |

| Crack-resistant | Low shrinkage reduces cracking and honeycombing |

| Smooth finish | Power troweling gives a uniform and glossy surface |

| Durable and long-lasting | Best for industrial and commercial floors requiring long service life |

| Low maintenance | Minimal upkeep after installation |

🔹 Common Applications in Indian Construction

Trimix Flooring is suitable for many types of projects in India:

- Factory flooring and machine shops

- Basement floors and residential parking slabs

- Cold storage units and warehousing spaces

- Loading docks and retail malls

This flooring system is especially preferred in infrastructure and real estate projects in India due to its cost-effectiveness and high durability.

🔹 Materials Used in Trimix Flooring

| Material | Purpose |

|---|---|

| Cement (OPC 43/53) | Binder for concrete mix |

| Sand (Fine Aggregate) | Fills gaps and improves workability |

| Coarse Aggregates | Adds strength to the flooring |

| Water | Required for hydration and mixing |

| Floor Hardener | Increases surface hardness and resistance |

| Steel Reinforcement | Improves structural strength and load-bearing |

Recommended concrete mix design: 1 : 1.5 : 3 (Cement : Sand : Aggregate)

🔹 Equipment Required

- Screed vibrator: For initial leveling of concrete

- Vacuum dewatering pump: Removes excess water from freshly laid concrete

- Power trowel or power floater: Gives a smooth finish

- Cutting machine: For groove cutting to control shrinkage cracks

These tools ensure a high-quality finish and increase overall floor performance.

Also Read Development Length in RCC: Essential Guide for Indian Construction Professionals

🔹 Step-by-Step Process of Trimix Flooring

Step 1: Surface Preparation

- Clean the area and compact the soil or base layer.

- Lay a PCC (Plain Cement Concrete) base with proper slope.

Step 2: Pouring of Concrete

- Prepare the concrete with proper mix ratio.

- Pour the concrete in panels using shuttering boards.

Step 3: Screeding and Vibration

- Use a double beam screed vibrator to level the concrete surface.

- Ensure even compaction to avoid honeycombs.

Step 4: Vacuum Dewatering

- Place suction mats over the surface.

- Use the vacuum pump to extract water.

- This reduces water-cement ratio and increases strength.

Step 5: Surface Finishing

- After vacuuming, use a power trowel to finish the surface.

- Apply a floor hardener for extra durability and wear resistance.

Step 6: Groove Cutting and Curing

- After 1–2 days, cut grooves or expansion joints using a cutting machine.

- These joints prevent shrinkage cracks.

- Start water curing and continue for at least 7 days.

🔹 Recommended Thickness for Trimix Concrete Flooring

| Application Area | Recommended Thickness |

|---|---|

| Residential Parking | 100–125 mm |

| Commercial Buildings | 125–150 mm |

| Warehouses & Industries | 150–200 mm |

Use proper reinforcement depending on floor usage and load type.

🔹 Cost of Trimix Flooring in India (2025 Estimate)

| Type of Work | Cost per sq.ft (₹) |

|---|---|

| Residential Parking | ₹75 – ₹90 |

| Commercial Use | ₹90 – ₹110 |

| Heavy Industrial Floors | ₹110 – ₹130 |

Note: Prices may vary based on floor thickness, floor hardener brand, labour rates, and region.

🔹 Maintenance Tips for Long Life

- Clean regularly with water and mild detergent

- Avoid oil spillage and corrosive chemicals

- Reapply sealant every few years

- Use rubber pads under heavy machines

Proper care ensures the flooring stays strong and shiny for 20+ years.

🔹 Difference Between Trimix and IPS Flooring

| Feature | Trimix Flooring | IPS Flooring |

|---|---|---|

| Strength | Very high | Moderate |

| Water removal | Uses vacuum dewatering | No dewatering |

| Surface finish | Smooth and glossy | Rougher finish |

| Load capacity | Heavy load resistance | Light to moderate load |

| Cost | Slightly higher | Lower initial cost |

| Life span | 20+ years | 5–10 years |

Trimix flooring is more suitable for modern Indian industrial flooring requirements.

🔹 FAQs

Q1. What is the life of Trimix Flooring?

It can last 20 years or more with proper curing and maintenance.

Q2. Is Trimix Flooring waterproof?

It is water-resistant, but not fully waterproof. Sealants improve its performance.

Q3. Can Trimix be used in homes?

Yes. It is ideal for parking areas, driveways, and basements in residential buildings.

Q4. How long does it take to complete 1000 sq.ft?

Usually 2 to 3 days, depending on curing time and manpower availability.

Q5. What is the ideal curing period?

Cure for at least 7 days to develop maximum strength.

🔹 Conclusion

Trimix Flooring is a smart investment for long-term durability, especially in industrial construction projects across India. Its vacuum dewatering system makes the surface strong, crack-free, and suitable for high-traffic areas.

Though the initial cost is slightly higher, the reduced maintenance, improved strength, and long lifespan make it highly economical in the long run.

If you’re looking for durable industrial concrete flooring in India, Trimix is the top choice. Follow proper guidelines, use quality materials, and hire skilled workers to get the best results.