The Specific Gravity Test of Cement is one of the most essential quality control tests in construction. It helps in determining the density of cement compared to water and directly affects concrete mix design, water-cement ratio, and overall construction quality.

For Indian civil engineers, site supervisors, and construction students, knowing how to perform this test accurately is crucial. In this guide, we cover everything—from definitions to step-by-step procedure, formula, IS codes, and FAQs.

🧪 What is Specific Gravity of Cement?

Specific gravity of cement is defined as the ratio of the weight of cement to the weight of an equal volume of water. Ordinary Portland Cement (OPC) typically has a specific gravity of 3.10 to 3.16.

If the value is lower than 3.10, the cement may be old or moisture-laden. If it’s above 3.19, it could contain impurities or be partially hydrated.

📌 Importance of Specific Gravity Test in Construction

In India, most concrete mix designs assume cement has a specific gravity of 3.15. Any variation can lead to incorrect water-cement ratio, affecting:

- Workability of concrete

- Final strength of structure

- Durability of mortar and concrete

- Volume of mix required

This test is especially critical in large-scale infrastructure, residential buildings, and highway construction projects where accurate mix proportions are crucial.

📖 IS Code for Specific Gravity Test of Cement

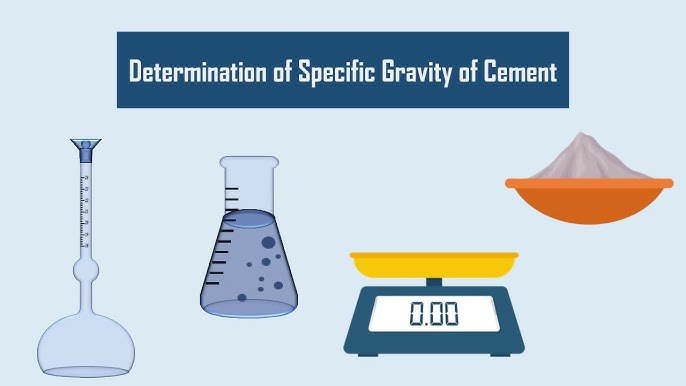

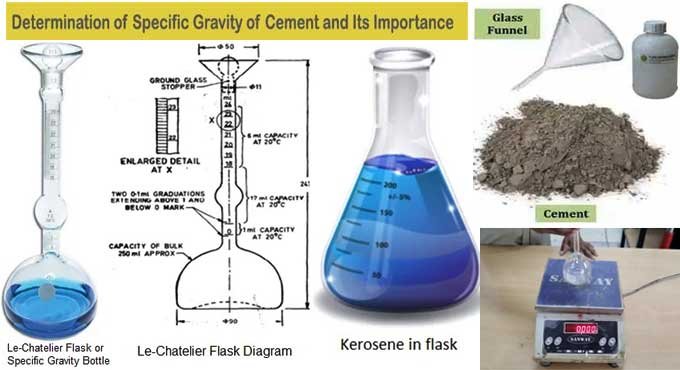

The test must be conducted as per IS: 4031 (Part 11) – 1988, which specifies the method for determining the specific gravity using a Le-Chatelier Flask and kerosene.

🧰 Equipment and Materials Required

| Equipment | Purpose |

|---|---|

| Le-Chatelier Flask (250 ml) | Measures cement and kerosene volume |

| Analytical Balance | Measures accurate weights (±0.1 g) |

| Kerosene | Non-reactive liquid used in the test |

| Ordinary Portland Cement (OPC) | Fresh sample, free from lumps |

| Water Bath / Room Thermometer | Maintains constant temperature (~27°C) |

⚙️ Step-by-Step Procedure to Perform the Test

- Weigh the empty, dry Le-Chatelier Flask. Note this as W₁.

- Add 64 g of dry cement into the flask. Gently tap to settle the cement.

- Record the weight of flask + cement as W₂.

- Add kerosene slowly until it reaches the graduated neck of the flask.

- Let it sit undisturbed at 27°C for 24 hours to remove air bubbles.

- Record the combined weight of cement + kerosene + flask as W₃.

- Empty, clean, and dry the flask. Fill it with kerosene up to the same mark.

- Record this weight as W₄.

Also Read Concrete Cube Compressive Strength Test: Step-by-Step Guide as per IS Code for Indian Construction

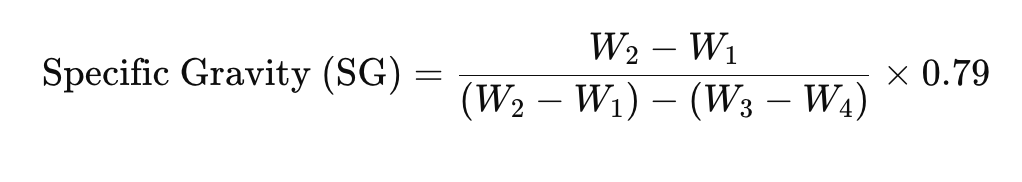

🧮 Formula for Specific Gravity of Cement

Where:

- W₁ = Weight of empty flask

- W₂ = Weight of flask + cement

- W₃ = Weight of flask + cement + kerosene

- W₄ = Weight of flask filled with only kerosene

- 0.79 is the specific gravity of kerosene

✅ Standard Specific Gravity Values and Their Meaning

| Specific Gravity | Quality Assessment |

|---|---|

| 3.10 – 3.16 | Fresh and good quality cement |

| < 3.10 | May be old or moisture-affected |

| > 3.19 | May contain impurities or moisture |

⚠️ Common Mistakes to Avoid

- Using water instead of kerosene – causes premature hydration

- Improper cleaning of flask – leads to inaccurate weights

- Not removing air bubbles – causes incorrect volume measurements

- Using old cement – affects test accuracy and concrete strength

🧱 Applications in Indian Construction Projects

The Specific Gravity Test is widely used in:

- RCC building construction

- High-rise structures

- Road and highway projects

- Mix design calculations for M20, M25, M30 grades

- Cement testing laboratories

- Ready Mix Concrete (RMC) plants

In India, most civil engineers and site engineers rely on this test to validate incoming cement batches before use in large structural projects.

🙋 FAQs – Specific Gravity Test of Cement

Q1. Why is kerosene used instead of water in the test?

Because water reacts with cement and causes hydration, which can alter the results.

Q2. How many trials are needed?

At least two trials. If the difference is more than 0.03, repeat the test.

Q3. Is this test applicable for all types of cement?

Yes, but specific gravity may vary slightly for PPC, PSC, or other blended cements.

Q4. What if the specific gravity is above 3.20?

It may indicate improper storage, high moisture content, or poor quality.

Q5. Can I perform this test on-site?

Yes, it can be done with basic lab setup at a construction site or material lab.

🏁 Conclusion

The Specific Gravity Test of Cement is not just a textbook experiment. It plays a critical role in ensuring construction quality in real-world projects across India. A deviation from standard values can lead to structural issues, cracks, and even failure over time.

By using simple tools like a Le-Chatelier flask and kerosene, civil engineers and contractors can check whether cement is suitable for use. Regular testing saves money, ensures safety, and leads to better long-term durability of structures.