Introduction

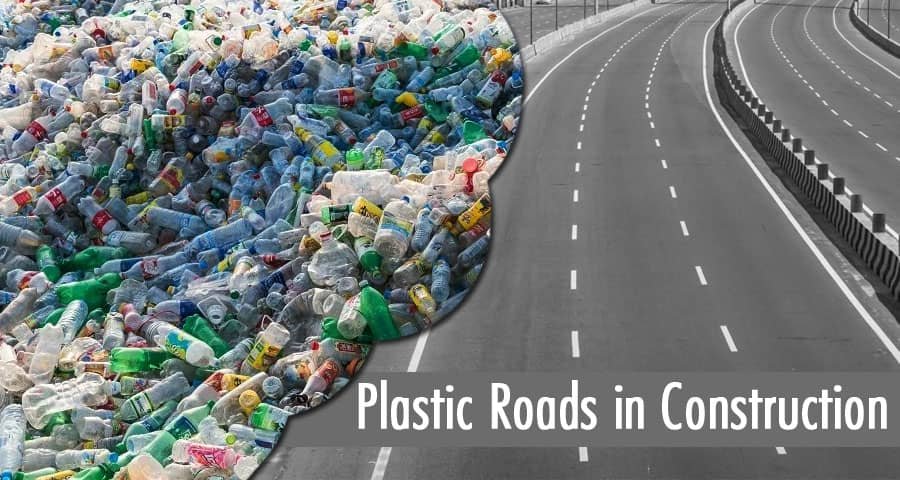

India has been facing two major challenges for decades — poor road conditions and the massive problem of plastic waste management. With increasing urbanization, the amount of single-use plastic waste generated has skyrocketed. On the other hand, traditional road construction often struggles with durability, especially under heavy rainfall and extreme temperatures.

Plastic roads present a unique solution to both problems. By mixing waste plastic with bitumen, engineers have found a way to create roads that are more durable, water-resistant, and eco-friendly. This method not only reuses waste materials but also improves the life span of roads in India.

What Are Plastic Roads?

Plastic roads are roads built using a combination of bitumen and shredded waste plastic. The process involves melting plastic waste and mixing it with hot bitumen, which is then laid as road surfacing material. This innovation was pioneered in India by Dr. R. Vasudevan, known as the “Plastic Man of India.”

Instead of letting plastic waste clog drains and pollute the environment, this approach transforms it into a valuable construction material.

Why Plastic Roads Are Important for India

India generates over 3.4 million tonnes of plastic waste annually, and a large portion is not recycled. At the same time, the country’s road network faces constant maintenance due to climatic conditions.

Using plastic in road construction helps:

- Reduce landfill waste.

- Improve road durability.

- Lower maintenance costs.

- Reduce environmental pollution.

Process of Constructing Plastic Roads

The construction process for plastic roads in India involves a few key steps:

| Step | Process Description |

|---|---|

| 1 | Collection of waste plastic such as carry bags, wrappers, bottles, and packaging material. |

| 2 | Cleaning and shredding plastic into small pieces (2–4 mm size). |

| 3 | Heating bitumen to 160°C. |

| 4 | Mixing shredded plastic into hot bitumen, where it melts and blends uniformly. |

| 5 | Laying the mixture on the road surface and compacting it. |

Case studies and Indian projects

| Location | Year(s) | Notes |

|---|---|---|

| Chennai and Pune (various stretches) | Since 2015 | Early adopters; field trials and wider implementation on local roads. |

| Meghalaya village pilot (community project) | Past years | Small rural projects converting local plastic into road layer. |

| Kolkata (Bidhannagar) pilot repairs | 2025 | Recent pilot for road repairs with locally shredded plastics under municipal program. SRC-SMEC |

Internationally, cities like Los Angeles and companies with plastified paving methods are experimenting with recycled plastic binders and modular “plasticroad” systems. These show diverse technical paths and potential for scale-up.

Advantages of Plastic Roads

Plastic roads offer several benefits over conventional roads:

| Advantage | Description |

|---|---|

| Higher Durability | Can last up to 10 years without major repairs. |

| Water Resistance | Plastic coating prevents water penetration and pothole formation. |

| Cost Savings | Requires less maintenance compared to traditional asphalt roads. |

| Eco-Friendly | Reduces plastic pollution and dependence on virgin asphalt. |

| Better Flexibility | Withstands heavy loads and temperature variations. |

Disadvantages and Challenges

While plastic roads have many benefits, they also face some challenges:

| Disadvantage | Description |

|---|---|

| Segregation Issues | Requires proper separation of plastics before use. |

| Toxic Fumes | If heated improperly, plastic can release harmful gases. |

| Limited Awareness | Many contractors are not trained in the technology. |

| Policy Barriers | Not yet fully adopted in all Indian states. |

Typical mix proportions and practical steps (dry process)

A commonly used field approach is:

- Collect and segregate thermoplastic waste.

- Shred plastic to 2–4 mm or flakes.

- Heat aggregates to mixing temperature (around 160–170°C).

- Add shredded plastic (usually 3–10% of bitumen weight or a certain % of aggregate mass depending on specification).

- Mix until plastic melts and coats aggregate.

- Add bitumen and complete mixing to required binder content.

- Lay and compact as per conventional hot mix asphalt practice.

Lab research and Indian pilot projects often use plastic addition in the range 6–10% by weight of bitumen or around 0.5–1.5% by weight of total mix, depending on the method and the plastic type. These values are indicative — follow project specifications and MoRTH guidance for exact dosing.

Applications of Plastic Roads in India

Plastic roads have been successfully implemented in several parts of India.

Some notable examples include:

- Tamil Nadu (pioneered the use in state highways).

- Mumbai (used plastic roads to tackle monsoon potholes).

- Delhi, Pune, and Bangalore have adopted them in select areas.

Government Initiatives

The Indian government has made it mandatory for plastic waste to be used in road construction in certain regions. The Ministry of Road Transport and Highways issued guidelines in 2015 encouraging the use of waste plastic in bituminous mixes for road construction.

Cost Comparison Between Conventional and Plastic Roads

| Parameter | Conventional Road | Plastic Road |

|---|---|---|

| Average Life Span | 5–6 years | 8–10 years |

| Maintenance Cost | High | Low |

| Material Cost | Moderate | Slightly lower due to waste reuse |

| Environmental Impact | Higher | Lower |

Future Scope

With continuous research, plastic road technology could be improved to make it safer and more efficient. If implemented nationwide, it could help India reduce millions of tonnes of plastic waste every year while enhancing its road network quality.

Conclusion

Plastic roads in India are a brilliant example of turning waste into a resource. By combining environmental responsibility with engineering innovation, India can build roads that are stronger, longer-lasting, and eco-friendly. With the right policies, awareness, and training, this technology can be scaled to benefit the entire nation.

FAQs

Q1. Who invented the plastic road concept in India?

Dr. R. Vasudevan introduced the concept in India.

Q2. Are plastic roads safe for the environment?

Yes, when constructed properly, they prevent plastic from entering landfills and oceans.

Q3. How long do plastic roads last?

They can last 8–10 years with minimal maintenance.

Q4. Which cities in India use plastic roads?

Mumbai, Pune, Chennai, Bangalore, and Delhi have implemented them in various projects.

Q5. What type of plastic waste is used?

Carry bags, wrappers, packaging films, and plastic bottles.