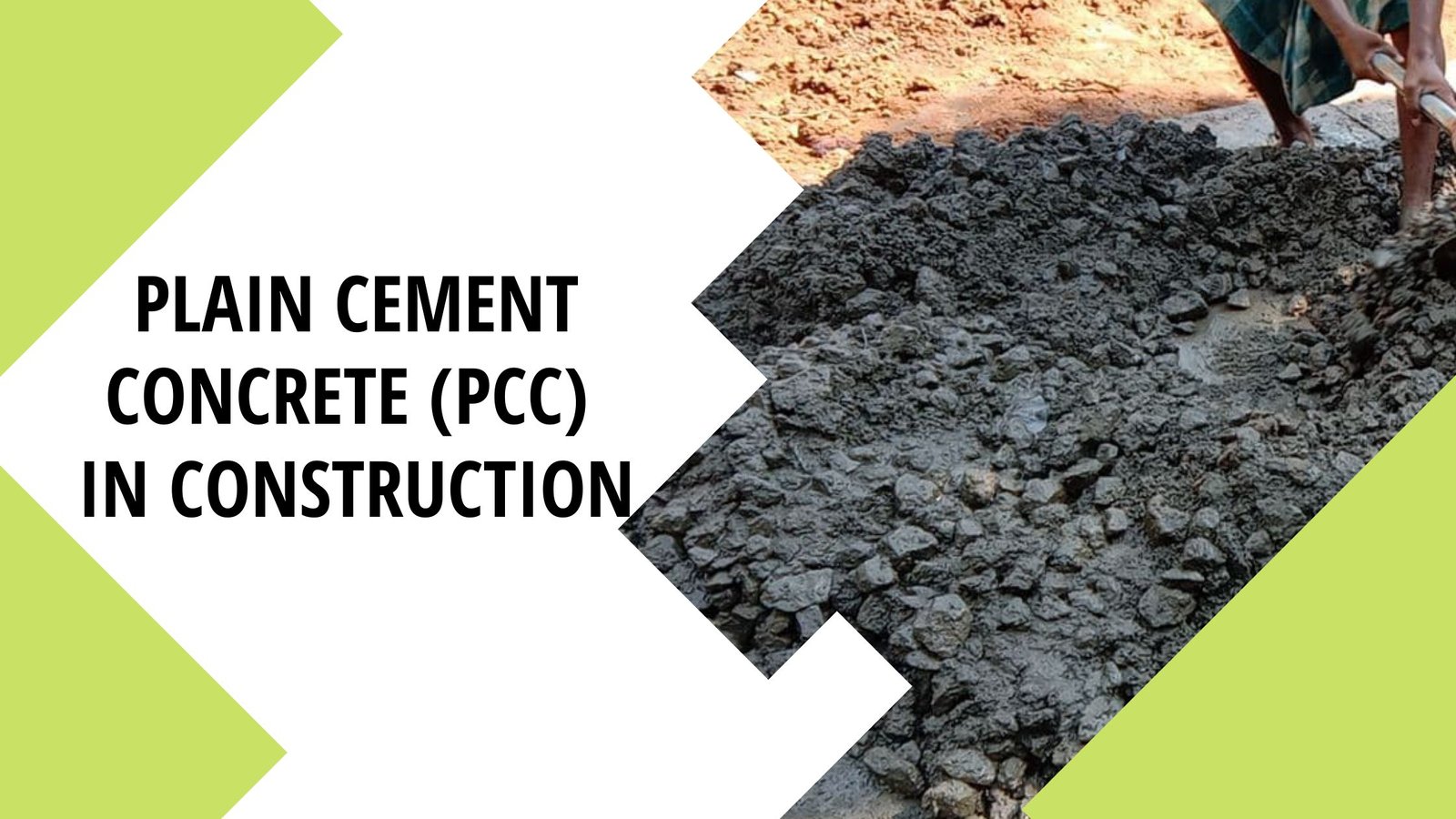

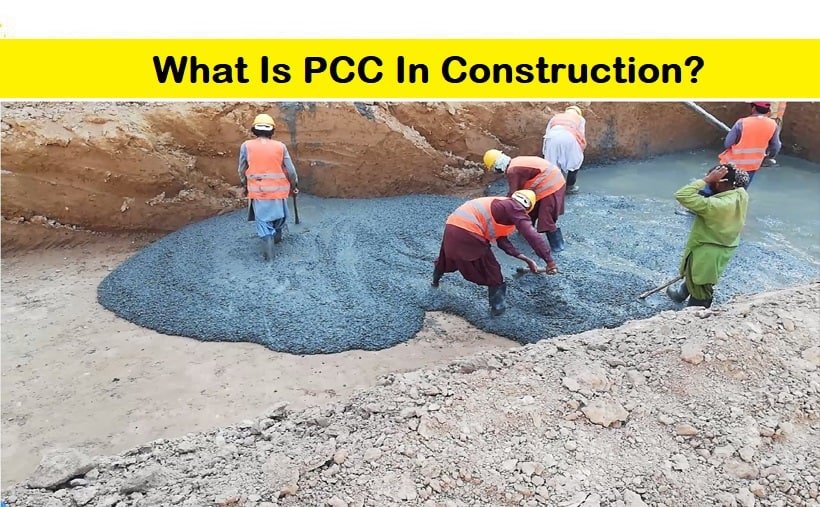

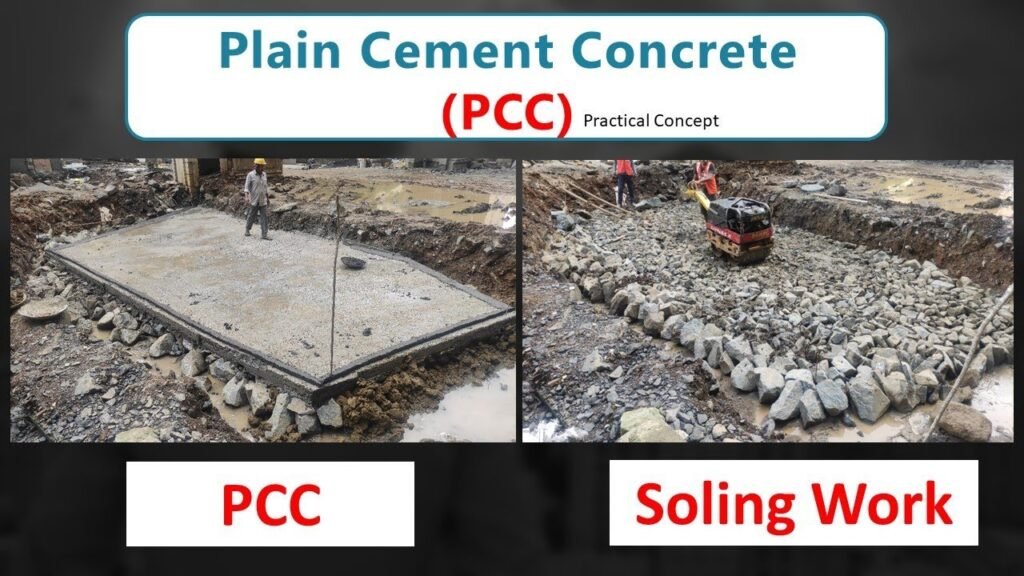

Plain Cement Concrete (PCC) is one of the most widely used materials in construction projects in India. It forms the base for foundations, flooring, and other structural elements. Understanding PCC grades, PCC mix ratio, and its applications is essential for civil engineers, contractors, and site supervisors.

This guide will explain PCC in detail, including its definition, uses, grades, proportioning, preparation, and quality checks.

What is Plain Cement Concrete (PCC)?

Plain Cement Concrete (PCC) is a mixture of cement, fine aggregate (sand), and coarse aggregate (gravel or stone chips) mixed with water. It does not contain steel reinforcement, which makes it different from Reinforced Cement Concrete (RCC).

In construction, PCC is generally used to provide a strong, level base and to protect reinforcement from soil contact and moisture.

Purpose of PCC in Construction

The main purposes of using PCC in building and infrastructure works include:

- Level Surface – PCC creates a smooth and level surface for laying structural elements.

- Moisture Barrier – It prevents direct contact of reinforcement with soil, reducing corrosion risk.

- Uniform Load Distribution – Helps distribute the load from the structure evenly.

- Foundation Support – Acts as a stable base for footings, columns, and walls.

PCC Grades in Construction

PCC is classified into grades based on its compressive strength after 28 days of curing. The most commonly used PCC grades in India are:

| Grade | Mix Ratio (Cement : Sand : Aggregate) | Compressive Strength (MPa) | Applications |

|---|---|---|---|

| M5 | 1 : 5 : 10 | 5 MPa | Levelling course, blinding layers |

| M7.5 | 1 : 4 : 8 | 7.5 MPa | Foundation bedding, flooring |

| M10 | 1 : 3 : 6 | 10 MPa | Base for RCC footings, road sub-base |

| M15 | 1 : 2 : 4 | 15 MPa | Pavements, small foundations |

| M20 | 1 : 1.5 : 3 | 20 MPa | High-strength flooring, heavy-duty works |

PCC Mix Ratio and Proportioning

The PCC mix ratio depends on the grade required for the project. The correct proportion of cement, sand, and aggregate is crucial to achieving the desired strength.

Example:

For M10 grade PCC (1:3:6 ratio):

- 1 part cement

- 3 parts sand

- 6 parts coarse aggregate

Water-Cement Ratio:

Typically between 0.4 to 0.5 for PCC, depending on workability requirements.

Materials Used in PCC

- Cement – Ordinary Portland Cement (OPC) 33, 43, or 53 grade is commonly used.

- Fine Aggregate – Clean river sand or manufactured sand (M-sand).

- Coarse Aggregate – Crushed stone or gravel, usually 20 mm size.

- Water – Clean, potable water free from salts and organic matter.

Step-by-Step PCC Preparation

1. Site Preparation

- Clear the surface of vegetation, loose soil, and debris.

- Mark the layout as per the design.

2. Formwork

- Wooden or steel formwork is fixed to hold the PCC in place.

3. Mixing

- Hand mixing for small works.

- Machine mixing for larger projects for uniformity.

4. Placing and Compaction

- Pour the mix evenly.

- Use vibrators or hand tamping to remove air voids.

5. Levelling and Finishing

- Level the surface using straight edges or trowels.

6. Curing

- Keep the PCC wet for at least 7 days to gain proper strength.

Also Read Difference Between Truss and Frame in Construction: A Complete Guide

Advantages of PCC

- Provides a stable and even base.

- Reduces the risk of reinforcement corrosion.

- Low maintenance.

- Increases durability of the structure.

Limitations of PCC

- Cannot handle tensile stresses.

- Not suitable for high-load structural members without reinforcement.

- Shrinkage cracks may occur if curing is inadequate.

Common Applications of PCC in Indian Construction

- Under footings and foundations.

- As a flooring base in residential and commercial buildings.

- As pavement base in road construction.

- As blinding layer before waterproofing works.

Cost of PCC in India

The cost of PCC depends on material rates, labour charges, and grade used. On average:

| PCC Grade | Approx. Cost (₹/m³) |

|---|---|

| M5 | ₹3,000 – ₹3,200 |

| M7.5 | ₹3,200 – ₹3,500 |

| M10 | ₹3,500 – ₹3,800 |

| M15 | ₹3,800 – ₹4,200 |

(Note: Prices vary by location and year)

Quality Checks for PCC

- Proper proportioning of materials.

- Clean aggregates free from dust and clay.

- Uniform mixing.

- Adequate compaction to remove air pockets.

- Continuous curing for at least 7 days.

FAQs on Plain Cement Concrete

Q1. What is the difference between PCC and RCC?

PCC does not have reinforcement, while RCC contains steel bars for strength against tensile forces.

Q2. What is the minimum thickness of PCC under footing?

Generally, 75 mm to 100 mm depending on the structure.

Q3. Can PPC cement be used for PCC?

Yes, but OPC is more common for faster setting.

Q4. Why is PCC used before foundation?

It prevents direct soil contact and ensures a level surface for the foundation.

Q5. How long should PCC be cured?

Minimum 7 days for better strength and durability.

Conclusion

Plain Cement Concrete (PCC) plays a vital role in the durability and stability of construction projects. Selecting the right PCC grade and ratio, using quality materials, and following proper mixing and curing methods ensures a strong and long-lasting base for any structure.

In India, PCC remains the first step in almost all construction activities, whether for small houses or large infrastructure projects. Proper planning and execution of PCC work lead to reduced maintenance costs and improved structural life.