Development length is one of the most important design parameters in reinforced concrete construction. Whether it’s a beam, column, footing, or slab, correct anchoring of steel bars ensures structural strength and long-term durability. In this article, we will explain everything about development length in RCC (Reinforced Cement Concrete), using simple language, formulas, IS code references, and real-world construction practices.

What is Development Length?

Development length is the minimum length of rebar (reinforcement bar) required to be embedded in concrete to develop its full tensile strength without slipping. It ensures the proper bond between steel and concrete, which is essential for structural safety.

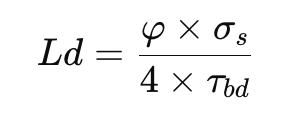

According to IS 456:2000 Clause 26.2.1, the development length (Ld) can be calculated using the following formula:

Where:

- φ = Diameter of the bar (in mm)

- σs = Stress in the bar at the design load (usually 0.87 × fy)

- τbd = Design bond stress (depends on grade of concrete)

Why is Development Length Important in Construction?

- Prevents slippage of reinforcement in concrete

- Ensures safe transfer of stress from steel to concrete

- Avoids premature cracking or failure of RCC members

- Required for proper anchorage in beam-column joints, slabs, and foundations

- Mandatory as per Indian Standards and design practices

Also Read Ultimate Guide to Specific Gravity Test of Cement for Quality Concrete in India

Design Bond Stress (τbd) as per IS 456

The bond stress value depends on the grade of concrete and type of bar used. Here is a table for deformed bars:

| Concrete Grade | τbd (N/mm²) for Deformed Bars |

|---|---|

| M20 | 1.92 |

| M25 | 2.24 |

| M30 | 2.40 |

| M35 | 2.72 |

| M40 & above | 3.04 |

Note: For bars in compression, increase τbd by 25%.

Example of Development Length Calculation

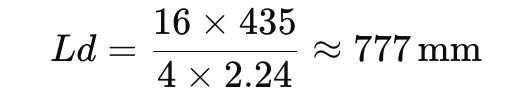

Let’s calculate development length for a 16 mm diameter bar in M25 concrete using Fe 500 steel:

- Bar diameter φ = 16 mm

- σs = 0.87 × 500 = 435 N/mm²

- τbd (M25 concrete) = 2.24 N/mm²

So, a 16 mm Fe 500 bar in M25 concrete needs a development length of approximately 777 mm.

Typical Development Lengths for Fe 415 Bars (Rounded Off)

| Bar Diameter (mm) | M20 Concrete (mm) | M25 Concrete (mm) | M30 Concrete (mm) |

|---|---|---|---|

| 10 | ~290 | ~250 | ~230 |

| 12 | ~350 | ~300 | ~270 |

| 16 | ~470 | ~400 | ~360 |

| 20 | ~590 | ~500 | ~460 |

Use this as a quick reference for preliminary design. Final values should be calculated.

Factors Affecting Development Length

- Type of Steel – Fe 415 or Fe 500

- Bar Diameter – Larger bars require longer development length

- Grade of Concrete – Higher grade means better bond

- Bar Type – Deformed bars have higher bond stress than plain bars

- Location in Member – Tension vs compression zones

- Concrete Cover – Adequate cover improves bond

- Spacing of Bars – Closely spaced bars affect concrete flow and bonding

Lap Splices and Hooks

Where the required bar length exceeds available rebar length, lap splices are used. The lap length is generally equal to development length, especially in tension zones.

Standard hooks (like 90° or 135° bends) are provided at bar ends to improve anchorage. However, hooks cannot replace straight development length—they support it.

Special Considerations for Bundled Bars

When two or more bars are bundled together:

- Increase development length by:

- 10% for two bars

- 20% for three bars

- 33% for four bars

This accounts for reduced bond surface area.

Development Length in Compression Zone

In compression members like columns:

- Steel is not subject to tension cracking

- IS 456 allows 25% increase in bond stress, reducing required development length

This is useful in column-footing junctions, pile caps, and base slabs.

Anchorage in RCC Structures

| RCC Element | Where Ld is Critical |

|---|---|

| Beam | Near supports, especially in cantilevers |

| Column | At junction with foundation or beam |

| Slab | At ends and over supports |

| Footing | At junction with vertical bars from columns |

| Staircase | Where tension reinforcement changes direction |

Proper anchorage length prevents structural failures in critical locations.

Common Construction Mistakes

- Ignoring hook length or providing insufficient anchorage

- Misunderstanding the difference between lap length and development length

- Incorrect τbd value due to wrong concrete mix or weather conditions

- Not considering bar bundling or bar congestion

- Neglecting site-specific modifications like chemical admixtures, poor compaction, or rebar corrosion

Development Length as per Indian Standards

- IS 456:2000 – Primary code for RCC detailing

- IS 13920:2016 – Earthquake resistant detailing (for seismic zones)

- SP 34 – Handbook for detailing of reinforcement

- IS 2502 – Bending and placing of reinforcement bars

These standards give guidance for bar hooks, bends, anchorage, lap length, and spacing.

FAQs – Development Length in RCC Construction

Q1. Is development length same for all concrete grades?

No. Higher concrete grades have better bond stress, reducing the required development length.

Q2. Can we reduce development length in compression zones?

Yes, IS 456 allows 25% increase in bond stress for bars in compression.

Q3. Is lap length same as development length?

No. Lap length is used to join two bars; development length ensures anchorage of one bar.

Q4. What if development length is not maintained?

It can lead to bond failure, cracks, and even structural collapse in extreme cases.

Q5. Can hooks or bends replace development length?

No. Hooks help, but full Ld must still be developed within the concrete.

Conclusion

Development length is a critical design and execution parameter in reinforced concrete construction. It ensures that rebars are safely anchored in concrete, allowing stress transfer without failure. Whether you’re a civil engineering student, site engineer, or supervisor, understanding and applying proper development length is essential.

- Always follow IS 456:2000 and SP 34 for guidance.

- Use the correct bond stress, steel grade, and concrete grade.

- Don’t ignore effects of bar size, spacing, and cover.

- Confirm Ld at site during bar placement before concreting.

Getting this one parameter right will help ensure structural safety, longer lifespan, and quality construction in Indian conditions.

Author- Ayush