Cement Concrete Roads (also known as rigid pavements) are widely used in India for highways, city streets, and industrial areas. They are known for their long life, high durability, and resistance to wear. Unlike flexible roads, concrete roads can withstand heavier traffic and require less maintenance.

In this article, we will explain the step-by-step construction process, important IRC codes, materials used, and answer some frequently asked questions.

Why Cement Concrete Roads Are Preferred in India

- Long service life of 25–30 years

- Low maintenance cost over time

- Good performance in extreme weather conditions

- Better suited for areas with heavy vehicle traffic

- Less deformation compared to bitumen roads

Standard Codes and Guidelines Used in India

| Code | Description |

|---|---|

| IRC:15 | Specifications for construction of jointed plain cement concrete pavement |

| IRC:44 | Guidelines for mix design of pavement quality concrete |

| IRC:57 | Procedures for sealing joints |

| IS 456 | General code for plain and reinforced concrete |

| IS 10262 | Concrete mix proportioning |

These codes help engineers maintain quality, safety, and durability during road construction.

Step-by-Step Construction of Cement Concrete Road

1. Site Preparation and Subgrade Work

- Remove topsoil, vegetation, and debris.

- Level the area and compact the soil properly.

- The subgrade must have good bearing strength.

- Check moisture content to avoid shrinkage cracks later.

subgrade preparation for concrete roads, road bed compaction, cement concrete pavement base layer

2. Construction of Sub-base and Base Course

- Sub-base is usually made of granular material or soil-cement mixture.

- Ensures uniform support and drainage.

- Thickness depends on traffic load and soil type.

granular sub-base, soil-cement base, rigid pavement foundation

3. Formwork Installation

- Formwork is placed on both sides of the pavement.

- Ensures correct slab height, slope, and alignment.

- Forms are coated with oil to prevent sticking of concrete.

concrete formwork road slab, side forms for concrete roads

Also Read Basalt Rock Price & Uses in India: A Practical Guide for Builders, Engineers & Buyers

4. Batching and Mixing of Concrete

- Use weigh batching for accurate proportions.

- Use well-graded coarse and fine aggregates.

- Water-cement ratio is crucial (typically 0.35–0.45).

- Admixtures like plasticizers can be used for better workability.

concrete mix design for roads, water cement ratio in pavement concrete, IRC concrete mix guidelines

5. Transportation and Placing

- Transport concrete quickly to prevent setting.

- Spread concrete evenly using manual or mechanical means.

- Avoid delays during placing to prevent cold joints.

6. Compaction and Surface Finishing

- Use vibrators (needle or screed) for proper compaction.

- Finish the surface with a trowel or straightedge.

- Apply broom finish for skid resistance.

compaction of concrete road slab, surface finishing for road pavement, vibrating concrete for roads

7. Curing

- Begin curing as soon as the surface is hard enough.

- Use water, wet hessian cloth, or curing compounds.

- Maintain curing for at least 7 to 14 days.

curing time for concrete road, curing methods for cement concrete slab

8. Joint Cutting and Sealing

- Joints help control cracks due to expansion and shrinkage.

- Types include contraction joints, expansion joints, and construction joints.

- Joints are filled with hot pour sealants or elastomeric compounds.

expansion joints in roads, contraction joint spacing, concrete road joint sealant

Table: Concrete Road Construction Summary

| Process Stage | Purpose | Materials Used |

|---|---|---|

| Subgrade | Load-bearing soil layer | Natural soil, compacted fill |

| Sub-base | Improves load transfer, drainage | Granular material, soil-cement mix |

| Formwork | Shape and guide concrete | Steel or timber forms |

| Batching & Mixing | Strength control and durability | Cement, aggregates, water |

| Placing & Compaction | Removes air voids, level surface | Concrete, vibrators |

| Curing | Strength gain and crack prevention | Water, burlap, curing compound |

| Joint Cutting & Sealing | Crack control and durability | Sealants, joint fillers |

Equipment Used in Cement Concrete Road Construction

- Batching plant or mixers

- Vibrators

- Transit mixers

- Screed board or roller

- Curing tanks or sprinklers

- Groove cutter for joints

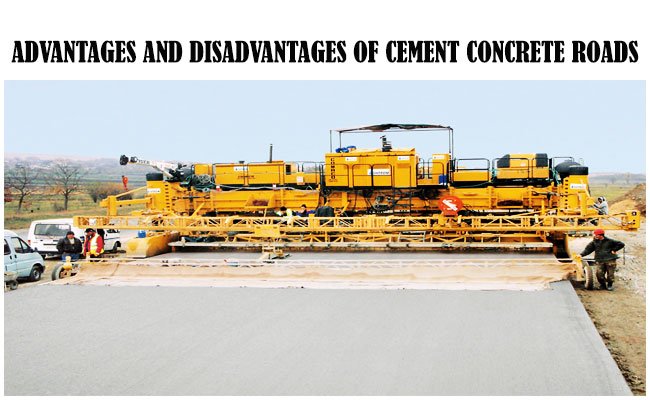

Advantages and Disadvantages

Advantages:

- High strength and load resistance

- Reduced maintenance costs

- Better visibility at night due to light color

- Suitable for national highways, rural roads, and industrial areas

Disadvantages:

- Initial cost is higher

- Construction takes more time

- Requires skilled labor and quality checks

FAQs – Cement Concrete Roads

Q1. What is the typical thickness of a concrete road in India?

Usually between 150 mm to 300 mm, depending on traffic loading.

Q2. What is the minimum grade of concrete for road construction?

M30 or higher is generally used as per IRC:44 guidelines.

Q3. Can we use fly ash in pavement concrete?

Yes. Fly ash improves workability and reduces heat of hydration.

Q4. What is the standard joint spacing in concrete roads?

Joints are typically spaced 4 to 5 meters apart for contraction joints.

Q5. What is the life expectancy of a CC road?

Well-constructed cement concrete roads last 25 to 30 years.

Conclusion

Cement Concrete Roads are essential for India’s growing infrastructure needs. They are strong, durable, and cost-effective in the long run. By following proper construction steps, using standard mix designs, and complying with IRC codes, engineers can ensure long-lasting road performance.

This guide provides a complete reference for civil engineers, contractors, and government agencies involved in rigid pavement construction across India.