Introduction

In India, testing the compressive strength of concrete cubes is a standard practice to ensure the concrete mix used in a structure can bear the required load. This test is vital for residential, commercial, and infrastructure projects. The most widely followed procedure is based on IS 516:1959 (Reaffirmed 2021).

This article provides a detailed explanation of the concrete cube compressive strength test, following IS standards, with step-by-step procedures, tables, and FAQs tailored for Indian civil engineers, contractors, and students.

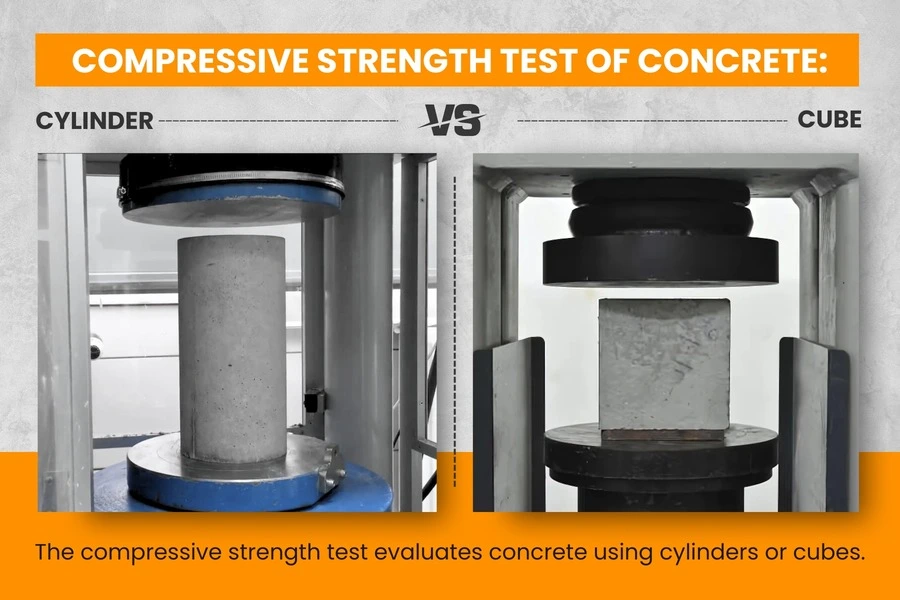

What Is Compressive Strength of Concrete?

Compressive strength refers to the maximum compressive load a concrete cube can bear before failure. It is a critical property of concrete. In most Indian construction projects, 150 mm cube specimens are used. The result is expressed in N/mm² (MPa).

Importance of the Compressive Strength Test

- Confirms concrete grade (M20, M25, M30, etc.)

- Ensures concrete meets structural safety standards

- Detects issues in mixing, compaction, and curing

- Mandatory for RCC structures and public works projects

- Helps track on-site concrete quality control

Indian Standards for the Test

| Standard Code | Description |

|---|---|

| IS 516:1959 | Test method for compressive strength of concrete |

| IS 456:2000 | General concrete construction code |

| IS 1199:1959 | Sampling and mixing procedures |

| IS 10086:1982 | Specifications for cube moulds |

Equipment Required

To perform the cube strength test, the following materials and tools are required:

| Item | Specification |

|---|---|

| Cube moulds | 150 mm × 150 mm × 150 mm (steel or cast iron) |

| Tamping rod | 16 mm dia × 600 mm long |

| Weighing machine | With 1 g accuracy |

| Compression Testing Machine (CTM) | Capacity 2000 kN; Loading rate 140 kg/cm²/min |

| Curing tank or water bath | Water at 27 ± 2 °C |

Aslo Read Top Construction Tools List: Essential Tools Used in Construction

Procedure of Cube Compressive Strength Test (IS 516:1959)

1. Concrete Sampling

- Collect fresh concrete from at least three different locations during pouring.

- Minimum 1 sample per 5 m³ of concrete poured.

2. Cube Mould Preparation

- Clean and oil the moulds before use.

- Place on a flat surface to ensure proper shape.

3. Cube Casting

- Fill moulds in 3 layers.

- Compact each layer with 25 strokes of the tamping rod.

- Overfill slightly and level the surface using a trowel.

4. Initial Curing

- Keep the cubes in a moist environment for 24 hours.

- Demould after 24 ± 0.5 hours.

5. Water Curing

- Place cubes in a water tank for curing at 27 ± 2 °C.

- Test cubes after 7 and 28 days.

Test Procedure Using CTM

- Remove cube from curing tank.

- Clean cube and allow surface water to dry.

- Place cube in Compression Testing Machine.

- Apply load at a uniform rate of 140 kg/cm²/min.

- Note down the maximum load at failure.

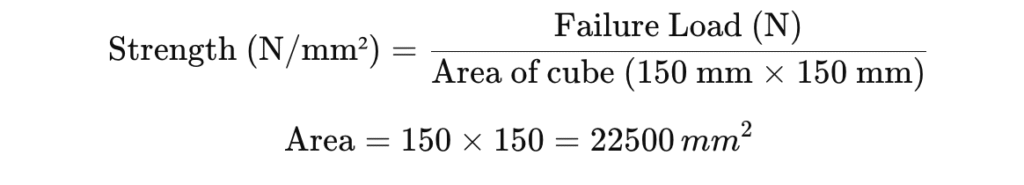

Compressive Strength Formula:

Cube Strength Acceptance Criteria (as per IS 456:2000)

| Concrete Grade | Minimum Compressive Strength (N/mm²) |

|---|---|

| M20 | 20 |

| M25 | 25 |

| M30 | 30 |

- Average strength of 3 cubes ≥ fck (e.g., 20 N/mm² for M20)

- Individual cube strength should not be < 0.85 × fck

Typical Strength Gain Over Time

| Age of Cube | Expected Strength (%) |

|---|---|

| 1 Day | 16% |

| 3 Days | 40% |

| 7 Days | 65% |

| 14 Days | 90% |

| 28 Days | 99%–100% |

This helps predict the final strength at early ages.

Frequency of Cube Testing

| Quantity of Concrete Poured (m³) | Minimum Samples |

|---|---|

| 1 – 5 | 1 |

| 6 – 15 | 2 |

| 16 – 30 | 3 |

| 31 – 50 | 4 |

| Above 50 | 4 + 1 per 50 m³ |

Each sample = 3 cubes → 1 for 7 days, 2 for 28 days.

Common Errors and Precautions

| Error | Prevention |

|---|---|

| Improper compaction | Ensure correct tamping |

| Poor curing | Use water tank at proper temperature |

| Moulds not aligned or damaged | Check and replace if worn |

| Rapid loading during test | Maintain constant rate |

FAQs

Q1. Why is 150 mm cube size used in India?

It is standardized as per IS 516. It balances ease of handling with accurate results.

Q2. What if cube fails the test?

Check the mix, curing, and placement. Retest may be needed. Non-compliance leads to rejection of concrete.

Q3. Is 7-day testing mandatory?

No, but it gives early idea of strength. Usually, 7-day strength is 65–70% of 28-day strength.

Q4. Can we use a non-destructive test instead?

Ultrasonic or rebound hammer tests are used for indicative results but do not replace cube tests.

Q5. What is the loading rate in CTM?

Apply load at 140 kg/cm²/min as per IS 516.

Conclusion

The compressive strength test of concrete cubes is one of the most reliable and important field tests in Indian construction. It validates the grade of concrete used and ensures compliance with IS codes.

By following the step-by-step method and keeping equipment and curing in check, site engineers can ensure quality control. It reduces the chances of structural defects, leading to longer service life of buildings and infrastructure.

Follow IS 516 and IS 456 strictly, record every result, and don’t skip 28-day testing—it’s the foundation of structural safety in civil engineering.

Suggested Tags (SEO Keywords)

- Concrete cube test

- Compressive strength of concrete

- IS 516 compressive strength

- 28-day concrete strength test

- Concrete cube testing India

- CTM test procedure

- Construction site concrete testing

- Civil engineering quality control

- RCC concrete grade test

- Cube test for M20 M25 M30