Clear cover is a small detail in reinforced concrete, but it plays a huge role in durability, safety, and service life.

Too little cover leads to corrosion of reinforcement, cracks, and spalling.

Too much cover can weaken the structure and cause wide cracks.

This guide explains what clear cover is, the difference between nominal cover and effective cover, IS 456 clear cover requirements, and best construction practices in RCC for Indian projects.

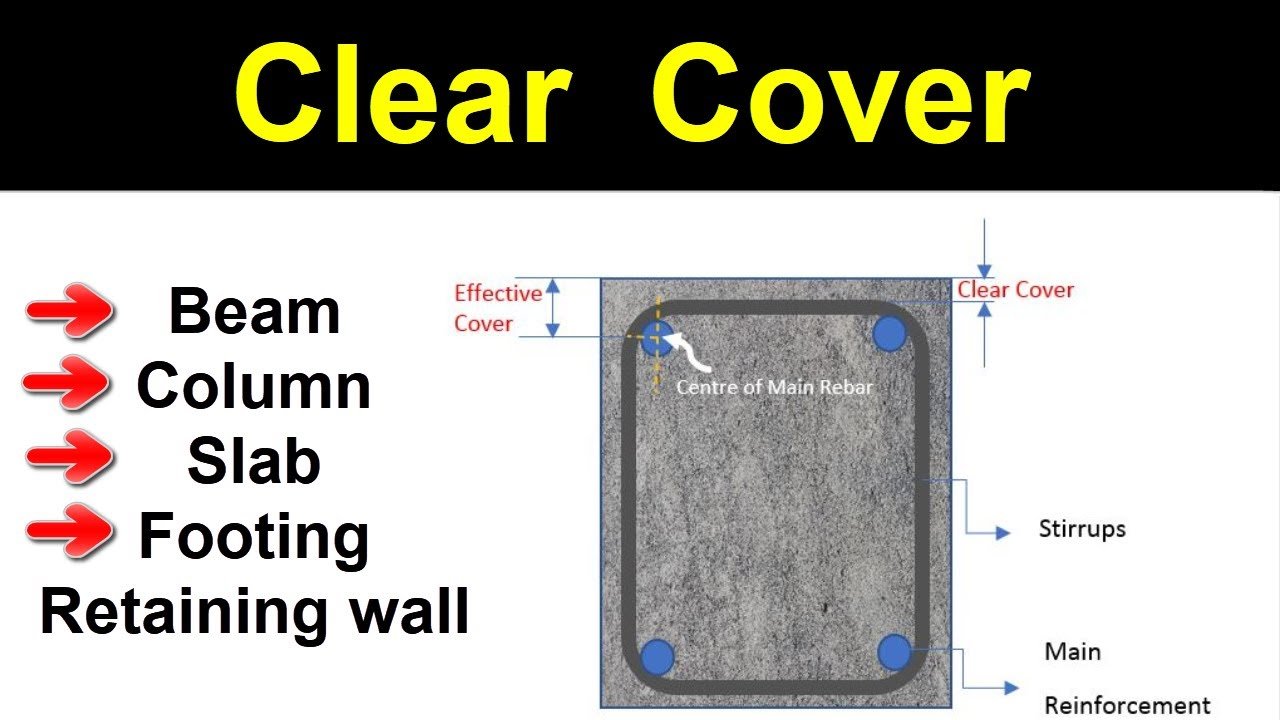

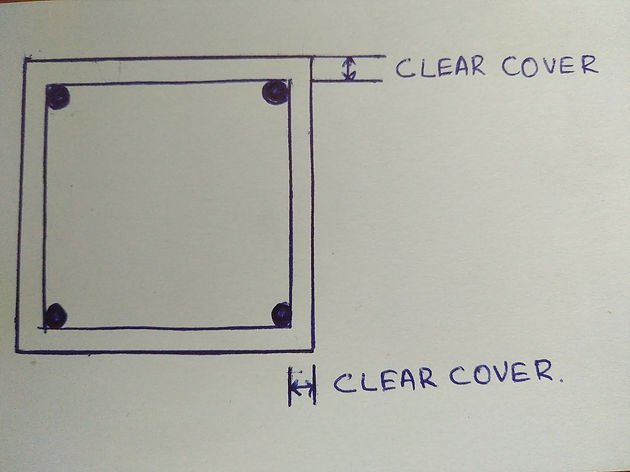

What is Clear Cover in Reinforcement?

- Clear cover is the shortest distance from the exposed surface of the concrete to the outer surface of the nearest reinforcement (including stirrups or links if they are the closest steel).

- Nominal cover is the cover specified in structural drawings to meet durability and fire resistance requirements.

- Effective cover is the distance from the extreme compression face of the concrete to the centre of the main reinforcement used in design calculations.

In simple terms:

- Nominal cover is what the designer specifies.

- Clear cover is what you actually achieve on site.

- Effective cover affects the structural strength.

Importance of Clear Cover in RCC Structures

- Durability – Protects reinforcement steel from moisture, oxygen, and harmful chemicals.

- Fire Resistance – Delays heat transfer to steel during a fire.

- Bond Strength – Ensures good bond between steel and concrete.

- Crack Control – Helps in controlling crack widths in RCC members.

- Structural Safety – Maintains designed load-bearing capacity.

IS 456 Clear Cover Requirements for RCC Construction

Indian construction projects follow IS 456:2000 for cover requirements. The code specifies nominal cover values based on environmental exposure and fire resistance.

Typical Nominal Cover Values as per IS 456

| RCC Member | Nominal/Clear Cover (mm) |

|---|---|

| Slab | 20 (or bar dia, whichever is greater) |

| Beam | 25 |

| Column | 40 |

| Footing / Raft | 50 |

| Pile Cap | 50–75 |

| Staircase Waist Slab | 20 |

| Retaining Wall | 25–40 |

Also Read Plain Cement Concrete (PCC) in Construction: Grades, Ratios, and Complete Guide

IS 456 Nominal Cover for Durability

| Exposure Condition | Examples | Nominal Cover (mm) |

|---|---|---|

| Mild | Interior, dry conditions | 20 |

| Moderate | Normal urban exterior | 30 |

| Severe | Coastal spray, polluted industrial air | 45 |

| Very Severe | Marine splash, alternate wetting/drying | 50 |

| Extreme | Direct seawater, aggressive chemicals | 75 |

Note: Always check the latest IS 456 code or project specifications.

Typical cover block sizes (illustrative):

| Member | Target cover | Common block size used |

|---|---|---|

| Slab bottom | 20 mm | 20–25 mm |

| Beam side/bottom | 25 mm | 25–30 mm |

| Column links/outer bars | 40 mm | 40–50 mm |

| Footing top/bottom | 50 mm | 50–60 mm |

Final sizes should reflect the nominal cover + tolerance set on drawings.

Cover for Fire Resistance

IS 456 provides separate tables for minimum cover to achieve specific fire resistance ratings (1 hour, 2 hours, etc.).

For example, a two-hour fire rating for a beam may require 50 mm nominal cover, even if durability alone requires less.

Clear Cover in Footings and Foundations

- Minimum clear cover: 50 mm (to protect against soil moisture and aggressive chemicals).

- In aggressive soils, increase cover or use protective coatings.

Cover Blocks – Maintaining Correct Clear Cover

Cover blocks are used to maintain required clear cover during concreting.

Best Practices:

- Use precast concrete cover blocks of equal or higher grade than parent concrete.

- Avoid using stone chips, wood, or brick pieces.

- For coastal areas, use polymer or fibre-reinforced cover blocks.

Common Sizes:

| Member | Target Cover (mm) | Cover Block Size (mm) |

|---|---|---|

| Slab | 20 | 20–25 |

| Beam | 25 | 25–30 |

| Column | 40 | 40–50 |

| Footing | 50 | 50–60 |

Best Practices for Achieving Proper Clear Cover

- Measure to the nearest steel (including stirrups).

- Place cover blocks at regular spacing.

- Check formwork alignment to avoid loss of cover.

- Prevent displacement during vibration.

- Use a cover meter to verify after concreting.

Common Mistakes in Clear Cover

- Using improper spacers.

- Reducing cover to fit bars.

- Ignoring tolerance limits.

- Not considering stirrups while measuring.

- Poor compaction leading to honeycombed cover zones.

Inspection Checklist for Site Engineers

- Drawings specify nominal cover for each member.

- Approved cover blocks are in use.

- Tolerance of 0 to +10 mm is maintained.

- Random checks using cover meter.

- Repair of damaged cover immediately after de-shuttering.

FAQs on Clear Cover in RCC

Q1. Is clear cover different from nominal cover?

Yes. Nominal cover is the design requirement, while clear cover is the actual distance achieved on site.

Q2. What is the minimum clear cover for slabs?

20 mm or bar diameter, whichever is greater, as per IS 456.

Q3. Why is more cover not always better?

Too much cover can cause wide cracks and reduce bond strength.

Q4. How do we ensure correct clear cover during concreting?

By using proper cover blocks, fixing reinforcement securely, and checking alignment before pouring.

Conclusion

Clear cover in reinforcement is a small but critical detail in RCC construction.

Following IS 456 clear cover requirements, using correct cover blocks, and maintaining quality control on site ensures durability, safety, and longevity of concrete structures in India.

Whether it is a slab, beam, column, or footing, correct clear cover is essential for structural performance and protection of reinforcement steel.