The Damp Proof Course (DPC) is a barrier laid in walls and floors to stop moisture rising from the ground. Selecting the right DPC material is key to preventing damp, mold, plaster failure, and structural damage. In this guide, you will learn how to choose DPC materials for Indian homes, commercial buildings, and heritage structures based on climate, wall type, and budget.

Why Selecting Correct DPC Material Matters

- Rising damp weakens mortar and bricks over time.

- Moisture stains, mold, and efflorescence reduce indoor air quality and aesthetics.

- A poorly chosen DPC may crack or corrode, failing to block moisture.

- Indian Standards like IS 2064 and IS 456 outline DPC guidelines for effective moisture control.

Key Properties of Effective DPC Materials

A reliable DPC should have:

- Complete water impermeability

- Strong and wear-resistant structure

- Dimensional stability—no shrinkage or warping

- No reactive salts like chlorides or nitrates

- Seamless jointing capability on site

These criteria ensure long-term moisture protection and structural durability.

Types of DPC Materials: Flexible, Semi-Rigid, Rigid

Flexible Materials

Used for damp or exposed surfaces:

- Bitumen felt sheets – inexpensive, easy to install, flexible

- Plastic or HDPE sheets – inert, UV-resistant, suitable for damp conditions

- Lead/copper/aluminium sheets – durable and corrosion-resistant in heritage use

Semi-Rigid Materials

- Mastic asphalt – smooth, seamless barrier ideal for basements and terraces

Rigid Materials

Used for plinth-level DPC:

- PCC (M15, M20) concrete (38–50 mm thick) topped with bitumen

- Dense / over-burnt bricks laid in cement mortar (1:3)

- Stone or slate slabs fixed in lime-cement mortar (1:1:6)

Chemical grouts and polymers are also used for remedial work or cavity trays.

Also Read Construction of Cement Concrete Road – Step-by-Step Process, IRC Guidelines, and Key Components

Material Selection Based on Location & Structure

| Building Location | Best DPC Material | Why It Works |

|---|---|---|

| Plinth level (residential & light structures) | PCC layer with bitumen | Strong, load-bearing, economical |

| Wet or flood-prone areas | HDPE or plastic sheet membrane | Waterproof, flexible, chemical-resistant |

| Large roofs, terraces, parapets | Bitumen felt or mastic asphalt | Seamless, fewer joints, accommodates movement |

| Thermally exposed walls | Mastic asphalt, metal sheet | Resistant to expansion/contraction |

| Cavities near lintels and sills | Lead strips or bitumen layers | Prevent bridges of damp across cavities |

| Budget construction | Dense brick or stone DPC | Low cost, available locally |

Installation Best Practices

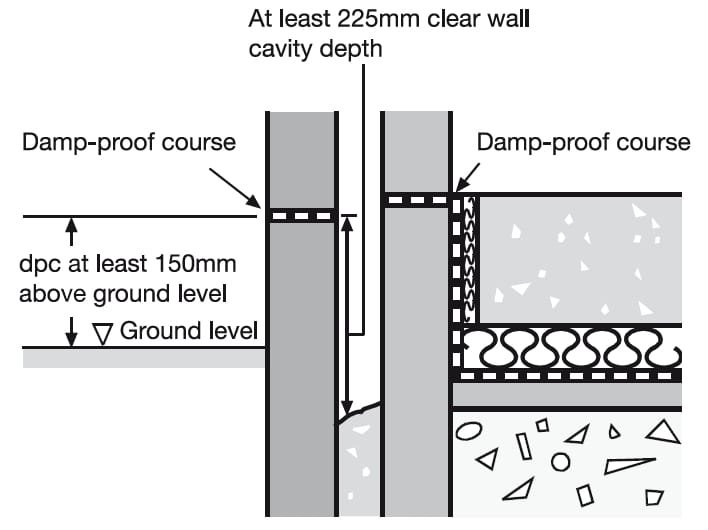

- Install DPC at least 150 mm above ground level.

- Ensure lapped joints of at least 100 mm for seamless continuity.

- Lay DPC on a clean, flat mortar bed with no sharp projections.

- At horizontal-to-vertical transitions, provide a 7.5 cm fillet of cement mortar.

- Continue DPC across the full thickness of the wall, excluding plaster.

- Embed flexible DPC fully into mortar joints and seal edges for continuity.

- For cavity walls, ensure DPC bridges both leaves and drains via weep vents.

Climate, Soil & Wall Factors to Consider

- High rainfall or humid climates: Use dense concrete (M20 or higher) with waterproof additives like Pudlo or Waterlock.

- Coastal or saline environments: Prefer inert plastic or copper lead membranes to prevent corrosion and chemical damage.

- Thin walls (<40 cm): Either rigid or flexible DPC may be used.

- Wall thickness >40 cm or where thermal movement occurs: Flexible materials absorb expansion and reduce cracking risk.

Advantages & Drawbacks for Popular DPC Materials

| Material | Advantages | Limitations |

|---|---|---|

| Bitumen felt | Affordable, flexible, easy to install | Prone to creep or tear under weight |

| Plastic/HDPE sheet | Chemically stable, durable, waterproof | Higher cost, needs precise joint sealing |

| Mastic asphalt | Seamless, dense, durable | Requires skilled installation |

| Metal sheets (lead/copper) | High durability, ideal for heritage | Expensive, requires bitumen coating |

| PCC with bitumen | Strong, supports structure above plinth | Hard to cut across corners, may crack |

| Brick or stone DPC | Cheap, locally available, simple to fix | Less effective in high moisture zones |

FAQs about DPC Material Selection

Q1: What is the recommended thickness for concrete-based DPC?

A typical DPC design uses 38–50 mm of rich concrete (M15 or M20), followed by two coats of hot bitumen.

Q2: Should bitumen felt be used in coastal buildings?

It can be used if protected properly. Otherwise, inert HDPE or metal sheeting is preferable to resist salt-induced degradation.

Q3: Can I use chemical DPC instead of sheet material?

Chemical DPC (resin-based treatments) is suitable for repairs or new walls with limited moisture. It often needs support from traditional materials.

Q4: Why use a fillet between horizontal and vertical DPC layers?

A mortar fillet ensures continuity without gaps at wall-to-floor junction and avoids moisture bypass.

Q5: Can integral waterproofing replace a DPC?

Integral waterproofing improves concrete permeability but should only supplement—not replace—a physical DPC layer.

Final Thoughts

Choosing the right DPC material for Indian building conditions is essential to prevent rising damp, structural damage, and long-term maintenance costs.

- Use concrete DPC at plinth levels.

- Use flexible membranes (bitumen, HDPE, mastic) where moisture, joints, or thermal movement are expected.

- Select rigid materials like stone or brick only where moisture risk is low.

Proper installation—correct height, lap joints, embedment, fillets—ensures moisture control and building health over time. Follow Indian Standards IS 2064 and IS 456 for compliance with building codes and long-lasting results.