Understanding the difference between BOQ (Bill of Quantities) and BOM (Bill of Materials) is critical in the construction and engineering field. These documents are often confused but serve very different purposes in a construction project.

If you are a civil engineer, contractor, site supervisor, or quantity surveyor in India, knowing how and when to use BOQ and BOM can save time, reduce cost overruns, and improve project coordination.

What Is a BOQ (Bill of Quantities)?

A BOQ is a comprehensive document that provides itemized details of materials, labour, and associated costs required in a construction project.

Key Features of BOQ:

- Lists quantities of materials like cement, bricks, steel, etc.

- Includes labour cost, equipment charges, and service fees

- Used during the tendering phase of construction

- Ensures uniform pricing when multiple contractors bid

- Helps in project budgeting and financial planning

- Prepared by quantity surveyors or cost estimators

BOQ is an essential tool for both government and private sector construction in India. It is widely used in projects governed by CPWD, PWD, and private real estate developers.

What Is a BOM (Bill of Materials)?

A BOM is a list of materials, components, and sub-components required to manufacture or assemble a product or system.

Key Features of BOM:

- Used in prefabrication, modular construction, and manufacturing

- Lists raw materials, part codes, product hierarchy, and specifications

- Helps manage inventory, procurement, and production

- Prepared by design engineers or production planners

- Includes only materials, not labour or unit rates

In Indian infrastructure projects, BOM is commonly used in precast construction, MEP fabrication, and structural steel detailing.

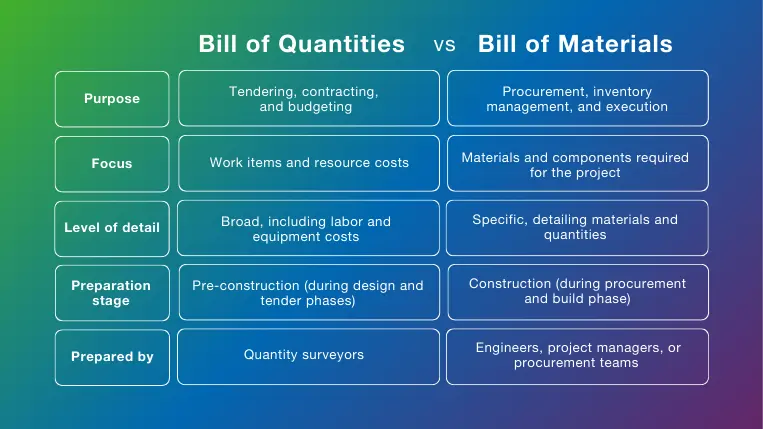

Key Differences Between BOQ and BOM

| Aspect | BOQ (Bill of Quantities) | BOM (Bill of Materials) |

|---|---|---|

| Purpose | Cost estimation, tendering | Material listing and production planning |

| Used By | Quantity surveyors, contractors | Design engineers, manufacturers |

| Includes | Material + Labour + Rates | Only materials and components |

| Measurement Unit | Cubic meter, Sq.m, Nos, Kg, etc. | Number of items or sub-components |

| Application | Site execution, billing, tender analysis | Factory production, inventory planning |

| Common In | Civil construction, roadwork, building projects | Prefabrication, modular building systems |

| Relevance in India | Essential for public works (CPWD, PWD, etc.) | Growing in precast and industrial construction |

When to Use BOQ and When to Use BOM?

Use BOQ When:

- Preparing estimates for residential, commercial, or infrastructure projects

- Participating in government or private tenders

- Allocating budget and tracking construction progress

- Generating contractor payments or client invoices

Use BOM When:

- Designing a precast concrete structure or steel framework

- Managing inventory of MEP materials or modular parts

- Prefabricating elements like staircases, door frames, or roof panels

- Procuring from multiple vendors for different component types

Also Read Basalt Rock Price & Uses in India: A Practical Guide for Builders, Engineers & Buyers

How Software and BIM Improve BOQ and BOM

Modern construction management software and Building Information Modeling (BIM) tools simplify the preparation of both BOQ and BOM. These platforms help:

- Automate quantity take-offs from architectural and structural drawings

- Reduce human error in calculations

- Generate real-time reports for project tracking

- Connect site teams with procurement and planning departments

In India, software like AutoCAD, Revit, Staad Pro, Primavera, and MS Excel are often used in combination with ERP systems to streamline BOQ and BOM documentation.

Example: BOQ vs BOM in a Residential Building Project

| Item | BOQ Entry | BOM Entry |

|---|---|---|

| RCC Staircase | 5 units, ₹15,000/unit (includes concrete, labour, shuttering) | Steel rods: 12 mm – 30 kg, M20 concrete – 0.5 m³ |

| Modular Kitchen Setup | ₹75,000 fixed price including carpentry, tiles, labour | Cabinet boards – 4, Hinges – 8, Counter slab – 1 |

| Precast Compound Wall Panel | ₹1200/meter including installation | Cement – 50 kg, Steel Mesh – 1 unit, Paint – 2 L |

This shows how BOQ gives the final payable cost, while BOM gives the material list for procurement and manufacturing.

Advantages of Using BOQ and BOM Together

- Improves accuracy in cost forecasting

- Supports faster project approvals

- Enhances coordination between design and site execution teams

- Minimizes material wastage and cost overruns

- Ensures smooth handover between engineering, procurement, and execution teams

In Indian mega projects like Smart Cities, Metro Rail, and Expressways, both BOQ and BOM are used for different purposes but contribute towards project success.

Frequently Asked Questions (FAQs)

Q1. Is BOQ used only in civil engineering?

Primarily yes, but it is also used in mechanical and electrical works during construction.

Q2. Can BOM replace BOQ?

No. BOM is material-focused and cannot provide cost breakdowns, labour inputs, or tendering structure like BOQ.

Q3. Who prepares the BOQ in Indian projects?

Typically, a quantity surveyor or billing engineer prepares the BOQ using project drawings.

Q4. Can BOQ be prepared using Excel?

Yes, many Indian firms use Excel with customized formulas and templates to prepare BOQs.

Q5. Does the Government of India use BOQs?

Yes. All tenders from PWD, CPWD, PMAY, NH projects, etc., are BOQ-based.

Conclusion

To run a successful construction project in India, understanding the difference between BOQ and BOM is not optional—it’s essential.

- BOQ helps estimate costs, plan budgets, and invite tenders

- BOM helps identify exact materials, track inventory, and streamline fabrication

Use BOQ for civil works, budgets, and site coordination. Use BOM for prefab, supply chain, and component-based construction.

By integrating both into your construction workflow, you’ll achieve better accuracy, lower costs, and smoother execution—key pillars of modern Indian infrastructure development.